Air atomizing nozzle flat spray

Design Features:

1. Inner structural design makes liquid and air mix fine, and then sprays fine. Normally, we could increase the air pressure or reduce the liquid pressure, so that we could make the nozzles spray more fine droplets (about 30micron).

2. Keeping liquid pressure and air pressure unchanged, as Adjustable air atomizing nozzle could adjust liquid flow rate, and then it also could spray according to your requirement.

3. Every spraying device consists of air cap and liquid cap. Spray pattern has flat fan, round, and wide- angle round spray. Nozzles also has widely flow rate. Inlet thread has different size which could be suitable for many pipe systems.

4. Air atomizing nozzle structure has pressure type, siphon type and gravity type.

Note: when you use air atomizing nozzle, air pressure is a should, but liquid pressure is not demanded. You could use pressure atomizing type with liquid pressure, while could use siphon atomizing type or gravity atomizing type.

5. Air atomizing device has two mixed type: inner mixed type and external mixed type. Inner mixed type could spray very fine, and it is suitable to use under many conditions. While, it is a good choose to use external mixed type to spray viscosity liquid.

6. There are two inlets in the nozzle body: liquid inlet and air inlet. We will mark “LIQUID” and “AIR” OR “L” and “A” on the nozzle. “LIQUID” AND “L” stands for liquid inlet, “AIR” and “A” stands for air inlet.

7. Air atomizing nozzle could spray very fine. it also could humidify environmental air very well. It is a ideal choose to use it in places need some certain humidify.

8. The air atomizing nozzle could spray a distance of 3 meter. Compared with high pressure fog nozzles, this kind of nozzle is easy to install, have a long live life, cheaper pipe lines, and so on. It is widely used in High-temperature Wax factory, cement plant, injection factory, Ceramics Factory, metallurgical factory and other places t o humidify, cool, dust removal, disinfection and so on.

Air atomizing nozzle made in China

Design Features:

1. Inner structural design makes liquid and air mix fine, and then sprays fine. Normally, we could increase the air pressure or reduce the liquid pressure, so that we could make the nozzles spray more fine droplets (about 30micron).

2. Keeping liquid pressure and air pressure unchanged, as Adjustable air atomizing nozzle could adjust liquid flow rate, and then it also could spray according to your requirement.

3. Every spraying device consists of air cap and liquid cap. Spray pattern has flat fan, round, and wide- angle round spray. Nozzles also has widely flow rate. Inlet thread has different size which could be suitable for many pipe systems.

4. Air atomizing nozzle structure has pressure type, siphon type and gravity type.

Note: when you use air atomizing nozzle, air pressure is a should, but liquid pressure is not demanded. You could use pressure atomizing type with liquid pressure, while could use siphon atomizing type or gravity atomizing type.

5. Air atomizing device has two mixed type: inner mixed type and external mixed type. Inner mixed type could spray very fine, and it is suitable to use under many conditions. While, it is a good choose to use external mixed type to spray viscosity liquid.

6. There are two inlets in the nozzle body: liquid inlet and air inlet. We will mark “LIQUID” and “AIR” OR “L” and “A” on the nozzle. “LIQUID” AND “L” stands for liquid inlet, “AIR” and “A” stands for air inlet.

7. Air atomizing nozzle could spray very fine. it also could humidify environmental air very well. It is a ideal choose to use it in places need some certain humidify.

8. The air atomizing nozzle could spray a distance of 3 meter. Compared with high pressure fog nozzles, this kind of nozzle is easy to install, have a long live life, cheaper pipe lines, and so on. It is widely used in High-temperature Wax factory, cement plant, injection factory, Ceramics Factory, metallurgical factory and other places t o humidify, cool, dust removal, disinfection and so on.

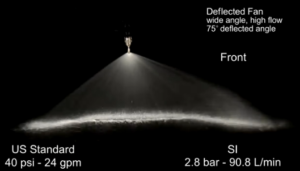

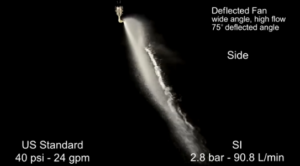

Deflected floodjet nozzle

Design Features of the deflect floodjet flat fan nozzle

One-piece construction

No internal parts

Sizes for all applications

Male and female connections

Extra-wide 145° spray angle

Medium-impact spray

Spray discharge deflected 75° from inlet axis

Coarse atomization

| Model No | CK Deflected Flat Fan Nozzle |

| Trademark | CNSS |

| Price/Payment | T/T 100% in advance |

| Standard | Can be customized |

| Productivity | 10,000PCS/MONTH |

Common Application:

Scrubbers

Rinsing

Cooling and quenching

Gas washing

Sand, coal, and gravel washing nozzle

Parts washing

Cooling and quenching

Spray pattern: Fan and Straight Jet

Spray angles: 105° to 145°

Flow rates: 0.2 to 757 L/min at 3bar

Standard Materials: 303 Stainless Steel, Brass, 316 Stainless Steel, PP, PVC, PVDF and PTFE

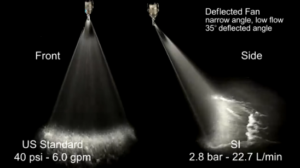

High Impact Flat Fan Nozzle

Design Features :

The precise alignment of the nozzle orifice with the deflector surface, and the low deflected angle produce a spray pattern with a narrow spray angle. (Choice of 15 to 50 degrees). Due to the thin line of the pattern, impact is higher than standard flat fan nozzles. A relatively large orifice is resistant to clogging.

One-piece construction

No internal parts

Sizes for all applications

Male and female connections

High impact

Uniform distribution with tapered edges for overlapping sprays

Extra-wide angles available

Common Application:

Scrubbers

Rinsing

Cooling and quenching

Gas washing

Sand, coal, and gravel washing nozzle

Parts washing

Cooling and quenching

Paper making

Spray pattern: Fan

Spray angles: 15°, 25°, 35°, 40°, 50°

Flow rates: 1.6 to 177 L/min at 3bar

Standard Materials: 303 Stainless Steel, Brass, 316 Stainless Steel, PP, PVC, PVDF and PTFE